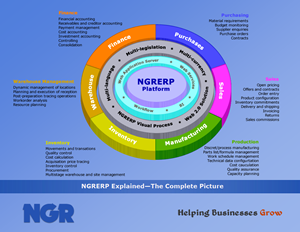

Planning Management

NGRERP business management software supports fully-integrated planning processes for single and multi-facility manufacturing and distribution organizations. The planning process begins with customer demand, which is comprised of sales orders and forecasts.

Manufacturers can run the material requirements planning (MRP) process which generates a series of purchase requisitions and tentative production schedules. Buyers and material planners can review the purchase requisitions to generate purchase orders and intercompany transfers, while manufacturing planners can review the tentative production schedules to generate final production schedules.

Distributors can run the distribution requirements planning (DRP) process which generates purchase requisitions to be reviewed and converted into purchase orders and intercompany transfers. For multi-facility organizations, NGRERP's DRP process can be used for centralized purchasing, facility-based purchasing, or as a combination of these methodologies.

Both the DRP and MRP processes enable distributors and manufacturers to establish realistic and achievable material and manufacturing plans to readily meet customer demand, improve customer service, decrease material and operational costs, and drive business profitability.

Forecasting

NGRERP software includes a sophisticated demand and sales forecasting software solution. Manufacturing and distribution organizations can manage an infinite number of forecasts in NGRERP, which can be entered manually or automatically generated through a series of algorithms to determine anticipated future demand on a product-by-product basis. Once created, forecastsare used as inputs to NGRERP's material requirements planning (MRP) and distribution requirements planning (DRP) processes.

Distribution Requirements Planning

NGRERP's distribution requirements planning (DRP) software functionality performs time-phased requirements planning for single and multi-facility distribution organizations. This process calculates inventory requirements over time and automatically generates online purchase requisitions, which can be turned into purchase orders and inventory transfers.

Material Requirements Planning

NGRERP's material requirements planning (MRP) functionality ensures raw materials, ingredients, and packaging supplies are available for production, to readily meet customer order requirements while optimizing inventory levels for improved discrete and process manufacturing efficiency.

NGRERP's material requirements planning (MRP) software functionality performs time-phased requirements planning for single and multi-facility manufacturing organizations. This process calculates inventory requirements over time and automatically generates online purchase requisitions and tentative production schedules, which can be turned into purchase orders, inventory transfers, and final production schedules.

Production Scheduling

In NGRERP, production schedules, consisting of a series of work orders, can be created manually and generated automatically. To generate the tentative production schedule, organizations establish a master production calendar which defines hours of operation by day and shift and the associated labor pool that will be available during those times.