Today’s business environment rewards those who can act faster and more efficiently, making the most of today’s most important asset—information. Many organizations face major challenges in their efforts to become smarter. Siloed information and poorly integrated business systems can make it difficult to act with speed and agility, which hurts competitiveness. NGR's ERP solutions can help answer these challenges.

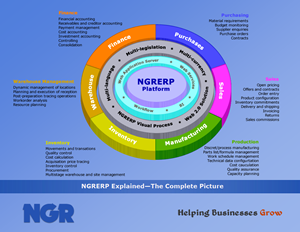

Whether you need to streamline your processes across procurement, manufacturing, service, sales, finance, or HR, an enterprise resource planning (ERP) solution from NGR can help transform your business. NGR's ERP / Business Management Solutions can help you to manage your ERP initiatives on a global basis with extensive business process knowledge, offering integrated, innovative strategy, change, and business advisory solutions in four key areas:

- Business strategy consulting

- Operations strategy

- Technology strategy

- Organization change strategy

NGR's powerful ERP solutions help make sense of information and use it to empower employees and organizations. Our sustained investment in best-in-class technology and services reflects a longstanding commitment to target our clients’ top-of-mind issues. Our ongoing efforts build on what makes these alliances so valuable to our clients worldwide—the complementary nature of leading enterprise applications with NGR strategic consulting, services, hardware and software. This combination helps our clients make the most of investments in ERP software to streamline and improve processes across any organization.

NGR's ERP solutions cover a wide range of functions and integrate them into one unified database. For instance, functions such as Human Resources, Supply Chain Management, Customer Relations Management, Financials, Manufacturing functions and Warehouse Management functions were all once stand alone software applications, usually housed with their own database and network, can now fit under one umbrella.

As in any integrated System or Unit, the performance of each one of the parts of an Enterprise has an impact in his cumulative performance results. Specifically, we can say that a 95% performance in independent vital enterprise elements (Item master, Bills of Materials, Production Master Schedule Adherence, Inventories Accuracy, Production Orders Accuracy and Purchase Orders Accuracy), will reflect a cumulative 75% in a ERP environment. This means a percentage of failure possible in productivity terms. Here is where we should support and combine this useful tool with a business strategy based on the desired administration tendency or theory.

Benefits: ERP helps small and midmarket businesses

An ERP package should provide an organization with a solid foundation, incorporating all of the fundamental aspects of running a business. Expectations run high when an organization deploys an ERP package - if the solution is a good fit for the company, the company stands to gain tremendous cost savings and service improvements across the enterprise.

Manual processes are automated, production scheduling is more efficiently managed and inventory is more accurately assessed. Also, business performance can be measured in a much more holistic fashion than ever before. This gives executives real-time visibility into all business processes, enabling them to make better strategic decisions. In short, with the right ERP package, a small or midmarket company can compete more aggressively in global markets.

According to a survey an ERP implementation can reduce costs in three primary categories: inventory costs, manufacturing operating costs and administrative costs. The survey's best-in-class respondents reported a 21 percent decrease in inventory costs, a 17 percent decrease in manufacturing operating costs and a 16 percent decrease in administrative costs. The average respondents' reductions were 11 percent, 8 percent and 9 percent, respectively.

Because an ERP solution has its fingers in all aspects of running a business, its benefits are myriad and go beyond tangible cost reductions. It can improve an organization's customer service and response time when solving issues. It can solve issues of interoperability among multiple manufacturing locations. It can standardize and accelerate manufacturing processes in all of a company's manufacturing sites.

It can streamline a manufacturer's order-fulfillment processes. It can facilitate connecting with partners' and suppliers' enterprise systems. ERP can even help an organization maintain compliance with government regulations, from hiring practices to environmental laws.

Case studies done on specific ERP implementations reveal a variety of different business-specific benefits. One of the case studies revealed that by replacing legacy systems with an integrated ERP package, one travel-accessories manufacturer reduced its inventory levels by 30 percent, reduced its warehouse space requirements by 38 percent, improved its month-end close process by five days, reduced its DSO (Days Sales Outstanding) by 44 percent and increased sales by 100 percent without hiring new employees.

Common ERP Myths

There are a lot of myths that surround the concept, infrastructure, implementation and practice of enterprise resource planning. Very often people are not willing to adopt ERP because of these wrong notions. In this section we will see some of the most common myths about ERP and will try to demystify them.

Properly implementing and managing an ERP system is not an easy task. The transition period from the traditional system or manual processing to ERP is difficult as new skills have to be learned; new procedures and processes have to be followed, and so on. Many employees think that ERP will add more work, make the work more difficult and will force unnecessary procedures. Transformation from the old system to the ERP system is a difficult process. However, if the management and the implementation team do their job properly, ensuring that the employees are told what to expect and given proper training, then the transition can be smooth. Once the employees get used to the new system, they will understand the potential benefits and the effort saved through automation of talks and jobs. Today's ERP tools automate many of the repetitive, monotonous and tedious procedures, tasks and processes thus making the life of the employees a lot easier.

Another popular misconception about ERP system is that its implementation will make many jobs redundant (because of the automation) and hence, many employees will lose their jobs. A properly implemented ERP system will automate many tasks in the organization. This does not mean that the ERP system will make people redundant. Yes, there will be changes in job descriptions and in the activities people used to do. Many tasks will be automated and this will make the people who were doing those jobs unnecessary. But ERP system also create new job opportunities and they very same people whose jobs were automated could be used to fill the new positions after giving them proper training on the new tasks. Hence, the amount of planning that goes into re-location and re-training of the employees by the management and the implementation team can go a long way in reducing the anxieties of the employees. ERP is a people system made possible by computer software and hardware.

Making an ERP system work is the responsibility of all the employees. It involves virtually every department and every person within the company. The company management is not responsible for the day-to-day operation of the ERP system. Their main job is to create an organizational environment in which ERP can thrive - give ERP the full backing of the management. They should also be involved in the development of ERP policies, usage guidelines, allocation of budget, package selection and appointment of competent professionals to implement and manage the ERP system. Only when the ERP team has the full backing and support of the management, they will be able to implement the system smoothly.

The management should monitor the implementation and operation of the system, review the progress and status periodically and should take necessary corrective action, if required. The management should also ensure that the ERP implementation team gets the support and co-operation of all the departments, But, thinking that the ERP system will succeed just because the management is fully committed to its implementation and operation is one of the biggest mistakes that an organization can make. In fact, it is the employees - the day-to-day users of the system - who will decide the fate of the ERP system. If the employees are not fully appraised, trained, satisfied and are not happy with the system and are not using it properly, then the ERP system will be a failure.

The managers and decision-makers are the major users of the ERP system. They are the people who benefit the most from the properly implemented ERP system. They will have all the information they need at their fingertips for making informed decisions. The quality of the decisions and the speed with which the decisions are made are dramatically improved as the ERP systems provide high-quality, timely and relevant information. But every employee in an organization benefits from the ERP system. An ERP system gives the store clerk access to the inventory record and enables him to find out the exact quality of an item. It allows the production supervisor to plan his activities. It allows all employees to apply for leave, get loads approved, gets the travel expenses reimbursed and so on.

But for making the best use of the information processing power of an ERP system the users should be trained on how to make the best use of the various features available. If people are ignorant about these, they will find it useless and if they are not properly trained, they will find the experience frustrating and tedious. These people will not use the ERP system or if forced will use it but not to its fullest potential. They will see ERP as a waste of time and do it just because they are forced to do it. This hostility towards ERP can be eliminated if the users are properly educated and make aware of the benefits of the ERP system.

This assumption is basically due to the way in which ERP was historically developed from the methods of Material Requirement Planning (MRP) and Manufacturing Resource Planning (MRP II), which are relevant to manufacturing organizations. In the manufacturing industry, MRP became the fundamental concept of production management and control in mid 1970s. At this stage BoM (Bill of Materials), which is purchase order management that utilizes parts list management and parts development, was the prevailing trend.

And this concept unfolded from order inventory management of materials to plant and personnel planning and distribution planning, which in turn became MRP II. This incorporated financial account, human resource management functions, distribution management functions and management accounting functions and came to globally cover all areas of enterprise mainstay business and eventually came to be called ERP. But in reality the concept of enterprise-wide planning of resource is not limited to any particular segment of industry.

The ERP implementation team usually consists of outside consultants, vendor representatives and select group of employees. But once the implementation and under training is over, the consultants and vendor representatives will leave. Then it is the responsibility of each and every employee of the company to use the ERP system properly and to make the best use of the new features and facilities.

Before the advent and popularity of ERP tools, most business tasks were performed manually and this was a time-consuming process. Often a lot of effort was duplicated. The ERP system automated the information flow across departments thereby eliminating duplication of efforts and faster and accurate results. In the case of an ERP system, an order can trigger a host of events that will take care of the materials procurement, production planning, invoice preparation, informing the suppliers, making and collecting payments and so on.

Today, the ERP system never functions in isolation. It is completely and seamlessly integrated with the supply chain tools and techniques right from customer relationship management to supply chain management to logistics management. This level of automation has dramatically improved the response time of organization and has helped them in serving the customers better. So an ERP system makes the organization efficient and never slows it down.

It is true that a properly implemented ERP system can help in serving the customers better as it helps the organizations to react faster, respond better and deliver high-quality products and services at astonishing speeds. This improved efficiency and quality will go a long way in improving customer goodwill and customer relations. So with an ERP system you get more satisfied customers, but that is only one of the advantages of an ERP system.

ERP is not a silver bullet or a cure-all. Yes, a properly implemented, operated and maintained ERP system can dramatically improve productivity, automate tasks, reduce wastage and improve profits. But an ERP system needs people to operate, use and maintain it. If the employees are not interested in using the ERP system or are using it improperly, if managers are not making use of the decision-making capabilities of the system or if the system is not maintained properly, then the ERP will not deliver it promises.

It is a fact that the ERP tools have evolved over-time and have now become very sophisticated. Today's ERP tools automate most business function and processes thus making the lives of the users a lot easier. But thinking that the ERP tools will take care of everything can be a recipe for disaster. There are many business activities that need human intervention and judgment. While the ERP tools make these jobs easier, there is no substitute for human intelligence and decision-making.

ERP packages come in all shapes and sizes. The sophisticated and high-end ERP tools are very expensive. ERP system needs people to manage it. Thus implementing and managing an ERP system is an expensive affair. But these expenses should be weighed against the benefits of the ERP system.

An efficient ERP system will increase the productivity of the human resources, shorten development and change cycles, streamline the production process, reduce errors by automating the monotonous and repetitive tasks, enable the better management of projects by providing quality information, improve customer satisfaction by resolving problems quickly and so on. When the benefits of the ERP system are considered, it becomes evident that the money spend on ERP is well spent and the ERP system will pay for itself.

Before the advent of ERP, organizations were run manually. So, do we need ERP in order to succeed? If an organization is very small in size, caters to the niche market and has very limited scope, then it can sometimes succeed without ERP. But today's organizations are becoming large and the products are becoming more and more complex in size, sophistication and technologies used. Also, a single group does not necessarily build the different components of a product.

This is the era of multi-site, distributed production, where different groups situated in different parts of the world develop the components of a system. In such a scenario, managing the activities of an organization is a very complex task. If proper control mechanisms and procedures are not in place, very soon the operations can get out of control and products and organizations can fail.