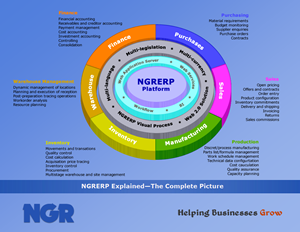

Warehouse Management

NGRERP includes complete, state-of-the-art warehouse management functionality that supports standard processes such as receiving, putaway, picking, replenishment, and shipping. The warehouse management functionality manages both single and multi-warehouse operations with transactions being performed both by keyboard and handheld and forklift-mounted RF-enabled barcode scanning devices. The warehouse management functionality is fully-integrated with the complete NGRERP suite, including purchasing, manufacturing, inventory, and financial management to provide a complete end-to-end solution for manufacturing and distribution organizations.

While optimized picking can be performed with traditional paper-based processes, greater productivity can be derived through NGRERP's directed picking and paperless task-interleaving processes. NGRERP manages and tracks the complete flow of material through the entire organization, from receipt and putaway of material, through production and kitting, and eventual picking, packing, and shipping to customers with complete lot traceability and serialization tracking. NGRERP also automates the management of other warehouse operations such as physical and cycle counts, vendor returns, license plating, and labor allocation and optimization.

NGRERP software provides the tools necessary for efficient and productive manufacturing and distribution operations. With NGRERP, organizations can improve their inventory accuracy, inventory turns, and customer service.

Wireless Warehouse and Barcoding

NGRERP's warehouse management functionality is fully RF and barcode-enabled. NGRERP supports barcode printing on forms such as pick tickets, packing slips, and work orders, and can print labels for products, locations, and pallet ID’s or license plates. In addition to on-demand barcode printing, all major warehouse management transactions can be performed directly using handheld RF-enabled barcode scanners. When using scanning technology, NGRERP can perform task interleaving, thus enabling warehouse efficiencies by directing the next highest priority task to warehouse personnel automatically. All activities are time stamped to allow for further warehouse productivity evaluation.

Warehouse Configuration

NGRERP's warehouse management functionality supports warehouse optimization and worker productivity. In the NGRERP system, zones, locations, and bins can be assigned to facilitate warehouse slotting, optimal inventory placement by product velocity group, and optimal pick path for improved worker efficiency.

Receiving

NGRERP's warehouse management functionality supports the recording of incoming material receipts via standard keyboard entry and handheld RF-enabled barcode scanners. Incoming receipts can be placed into segregated inspection locations, directly into active inventory, or in cross-docking locations. In addition, product labels can be applied when such labeling has not already been included by the supplier.

Inventory Putaway

The NGRERP business software suite can perform inventory putaway in a variety of methods including fully directed, straight to stock, or dock to stock. At the time of putaway, bar code labels or license plates can be printed and applied to the product. As with other NGRERP's warehouse management operations, these transactions can be performed using a keyboard or a handheld RF-enabled barcode scanner. NGRERP offers a flexible inventory putaway solutions tailored to each manufacturer's or distributor's warehouse requirements.

Pick Methods

The NGRERP system supports a variety of picking methods including pick by order, pick by area, cart picking, zone picking, wave picking, and pick queue processing. NGRERP enables manufacturers and distributors to have complete control over picking processes with flexible picking rules definition and selection criteria. NGRERP's warehouse management system allows an organization’s picking rules to be defined differently at various times during the business day, within months and quarters, and at year end. NGRERP also offers a directed picking environment which systematically balances employee work loads. Through NGRERP's flexible picking methods, manufacturers and distributors can optimize their pick, pack, and ship operations.

Shipping

NGRERP's warehouse management functionality supports manufacturers and distributors various shipping requirements from small package to LTL to full truckload shipments. NGRERP seamlessly integrates with common carriers' shipping systems, including UPS and FedEx. All shipping information and associated tracking numbers are available to customer service personnel and can be accessed via the customer’s e-Commerce account or transmitted to the customer via EDI.

Intercompany Management

NGRERP seamlessly tracks and documents all material movement and generates all accounting entries associated with intercompany transfers. Intercompany transfers can be entered manually and generated automatically by establishing the internal supply chain within the organization. NGRERP tracks in-transit inventory from shipment to receipt to provide complete visibility during the transfer process. In addition, NGRERP monitors and tracks transfer pricing and creates all necessary intercompany financial transactions.

Transportation Management

The NGRERP business management system includes transportation management functionality to allow manufacturing and distribution organizations to manage their complete transportation requirements. NGRERP includes the definition of carriers, lanes, contract terms, and freight rates to support load planning, freight rating, and route optimization. NGRERP gathers shipment and delivery data to calculate and evaluate carrier performance.